How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a significant development in quality control approaches. By using real-time, specific measurements of Fibre diameters, this innovation resolves the crucial requirement for uniformity in production criteria.

Relevance of Fibre Diameter Dimension

Precise measurement of Fibre Diameter is crucial in the field of optical Fibre modern technology, as it directly affects the efficiency and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission effectiveness. Accuracy in determining Fibre Diameter ensures that the optical homes are preserved within specified resistances, which is vital for ideal signal integrity.

Variations in Fibre Diameter can bring about raised losses because of scattering and modal dispersion, affecting the high quality of data transmission. In high-speed interaction systems, such disparities can lead to significant destruction of signal high quality, causing data errors and decreased performance. Constant Fibre Diameter is vital for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre production greatly rely upon precise Diameter measurements to ensure compliance with sector requirements. By implementing durable measurement strategies, producers can boost product integrity, minimize waste, and enhance overall system performance. Hence, the relevance of Fibre Diameter measurement can not be overemphasized, as it functions as a keystone in the development of optical Fibre modern technology and its applications in modern interaction networks.

How the Analyser Functions

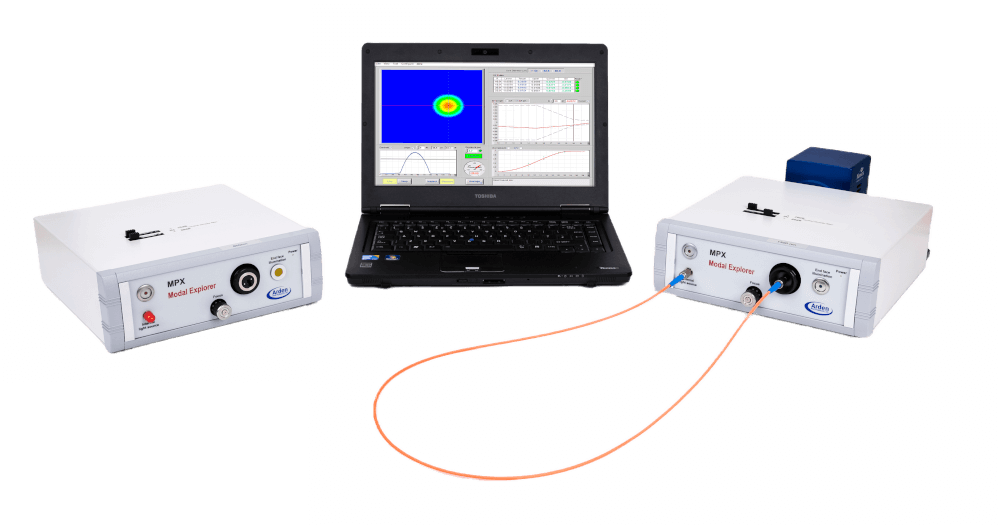

The effective measurement of Fibre Diameter counts on sophisticated logical techniques that guarantee accuracy and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture handling formulas to properly analyze the Diameter of fibres as they are created

Originally, a laser light beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this shadow making use of high-resolution cams positioned strategically along the assembly line. The caught pictures are after that refined in real-time to establish the Fibre's Diameter with outstanding accuracy.

The system uses sophisticated algorithms that represent different aspects, consisting of variants in light strength and environmental conditions, to enhance measurement reliability. It can spot minute modifications in Diameter, such as changes that might occur during the manufacturing process.

In addition, the analyser can managing several fibres at the same time, increasing throughput without endangering precision. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a critical duty in preserving stringent quality assurance criteria, making sure that the end product meets sector specs and customer needs.

Benefits of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter frequently entail lengthy post-production checks, real-time monitoring significantly enhances the performance and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive method permits makers to identify variances in Fibre Diameter as they take place, as opposed to waiting till production is total to assess high quality

By continuously gauging the Diameter during manufacturing, producers can make certain that the fibres satisfy rigorous specifications, bring about reduced variability and boosted consistency. Real-time surveillance also allows prompt corrective actions to be taken, decreasing waste and preventing faulty fibers from getting in the supply chain.

Additionally, this modern technology facilitates improved information collection and evaluation, providing insights into production patterns and possible locations for improvement. Such data-driven decision-making empowers producers to enhance procedures and keep high standards of quality assurance.

In addition, real-time tracking promotes a society of continual renovation within the production environment. Workers are much more engaged when they can see the effect of their operate in real-time, causing enhanced liability and a dedication to quality. Generally, the execution of real-time monitoring systems in optical Fibre production converts to premium item top quality and boosted client fulfillment.

Influence on Manufacturing Effectiveness

Executing optical Fibre Diameter analysers significantly boosts manufacturing effectiveness by improving the manufacturing process. These tools promote constant surveillance of Fibre Diameter, permitting suppliers to detect deviations in real-time. By recognizing incongruities immediately, assembly line can be readjusted swiftly, lessening downtime and decreasing the likelihood of generating faulty products.

Furthermore, the assimilation of learn this here now these analysers into the manufacturing process enables much better resource appropriation. With precise Diameter dimensions, operators can maximize material Get More Info use, making sure that resources are not lost on mistaken fibres. This accuracy likewise adds to less junk and remodel, inevitably reducing manufacturing costs.

The automation provided by optical Fibre Diameter analysers reduces dependence on manual examinations, which are susceptible and usually lengthy to human mistake. Because of this, workers can focus on more critical tasks, improving total productivity.

Moreover, the data produced from these analysers can educate process improvements and assist in better decision-making. By evaluating patterns in Fibre Diameter variations, makers can implement proactive procedures to boost manufacturing techniques and preserve constant top quality. In recap, optical Fibre Diameter analysers play an important role in increasing manufacturing performance, leading to better outcome and boosted productivity.

Case Studies and Success Stories

Across various industries, case research studies highlight the transformative impact of optical Fibre Diameter analysers on production processes. One popular example is a leading telecommunications company that faced difficulties with irregular Fibre sizes, resulting in enhanced being rejected rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre dimensions, leading to a 30% reduction in problems and significant cost savings.

Additionally, a research establishment concentrating on innovative materials used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to supply detailed understandings into Fibre uniformity enabled the advancement of cutting-edge materials with better performance attributes.

These success tales underscore the crucial role of optical Fibre Diameter analysers in enhancing top quality control, improving manufacturing performance, read this post here and driving development throughout varied industries.

Final Thought

Finally, the Optical Fibre Diameter Analyser plays an essential duty in enhancing quality assurance within Fibre manufacturing. By providing accurate, real-time dimensions and promoting immediate corrective actions, this innovation dramatically reduces variability and lessens waste. The execution of such innovative tools promotes a society of continual renovation and functional performance, ultimately guaranteeing compliance with industry requirements and preserving competitiveness. As demonstrated with different instance studies, the analyser proves crucial for achieving remarkable item top quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers allowed for rigorous quality control, making sure that the produced fibers fulfilled exacting market criteria.In conclusion, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production.